Now days, every yacht owner want to keep their yachts more attractive and good looking so that they look more stylish and luxurious. These people never want to compromise with the products quality so they are always looking for best quality of products for their yachts in markets. For that different types of products are available in market but most of the people cant able to find best quality from market as they get limited collection of choice in markets. In that situation, you should always prefer reputed online stores where you always find your best without any hassle.

Further, yachts look more stylish and luxuries when you are using best quality of furniture. For buying best quality of furniture for yachts you should always visit reputed online stores. At reputed online store you will always find latest design of furniture that is made of high quality materials. Not only have that, at reputed online stores you will also find best price as compare to others available in market. Along with that, at reputed online store you will always find wide range of collections so you can easily find your best choice without any hassle. Thus, to get premium quality of superyacht furniture at affordable price then must visit reputed online stores.

Read More: Enjoy Simple Boat Building Plans And Tricks

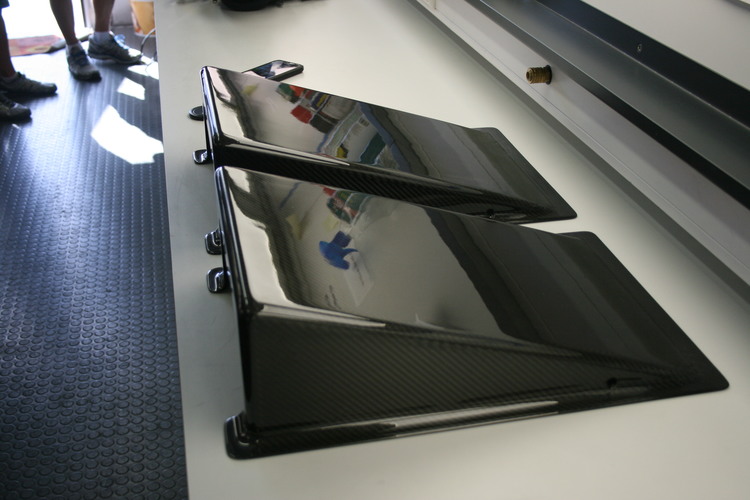

Many people always look for best quality of fiber glass for their yachts that are made of high quality materials as well as available at best price. In this regard, you can buy these products for your yachts from reputed online stores. At reputed online stores you will always find genuine and original products so you will never get disappointments while using it. Apart from that when you visit reputed online stores you will find different types of offers through which you can buy your best choice at affordable rate of price.