Passarelles are an excellent, safe, and fast way to onboard in the superyacht. Passarelles from a reputed company are meticulously crafted to provide your guests and employees with an attractive and timeless entry.

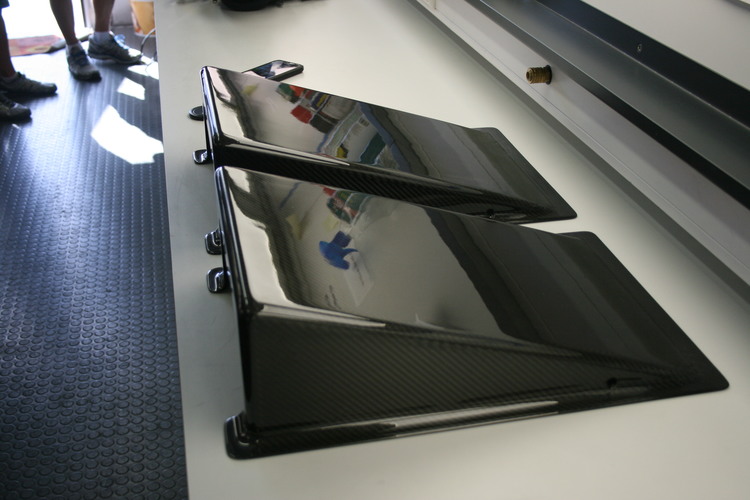

You can choose from various basic modular systems or fully customized boarding equipment to match your needs and requirements. At i3composites, we use the best materials to provide complete service and help during the process. The material quality also ensures optimum safety while operating.

Single-telescoping Passarelle

The single-telescoping type Passarelle improves the plank’s stowed efficiency and deployed flexibility. The telescoping part of the Passarelle can be extended or retracted when used. As a result, the pocketing hydraulic Passarelle can be used in a wide range of boarding situations.

Double telescopic Passarelle

The double-telescoping type passarelle develops the single-telescoping type passarelle, and its design improves the plank’s stowage efficiency. As a result, the hydraulic Passarelle can be stowed in smaller locations on the yacht. The telescoping parts of the passarelle can be extended or retracted when used. As a result, the hydraulic passarelle can be used in a wide range of boarding situations.

Fold-over telescoping passarelle

A fold-over passarelle is a common type for vessel designs with higher deployment length requirements or constrained stowage space. In terms of stowed and deployed ratio, the folding design is the most efficient. When stowed, the passarelle folds into a stack.

Fold under telescoping passarelle

Like the fold-over passarelle, the fold-under passarelle is designed for vessels with limited storage capacity or a need for increased deployment length. The folding design is the most efficient in terms of the stowed and deployed ratio. This ratio is even better when the folding plank part also incorporates a telescoping plank section. When stowed, the passarelle folds into a stack.

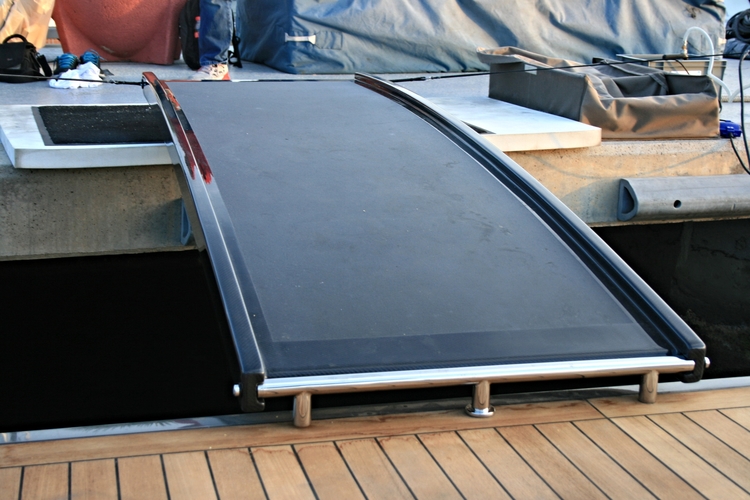

Jack-knife passarelle

In a jack-knife movement, the passarelle turns to starboard and stows beneath the transom hatch. When the hatch is closed, the superyacht name is visible.